New greenhouse harvesting technology for the industry

Canada’s greenhouse vegetable sector is booming but the cost and availability of human labour is a challenge across the sector. Harvesting is one of the most labour-intensive tasks and is a prime target for automation. The key to bringing a feasible harvesting robot to market is designing a system that is up to the task of replacing the accuracy and precision of a human.

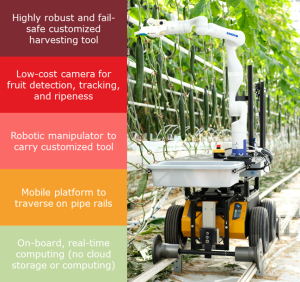

Leveraging our unique experience marrying robotics and computer vision with the intricacies of horticultural and biological objects, Vineland has developed a proof-of-concept harvesting robot for long English cucumbers and bell peppers. This patent-pending technology has been uniquely designed for safety and reliability. Supported by funding from Agriculture and Agri-Food Canada, Vineland undertook a project to develop a solution that is low cost, flexible and reliable. This has been achieved by relying on readily available off-the-shelf components. The rail cart, robotic arm and simple camera used in Vineland’s demonstration unit have been assembled with little customization, meaning the robot design and major components are adaptable. The magic is in a custom, patent-pending end effector for long English cucumber harvesting and associated computer vision and decision support software. The end effector features a revolutionary “closed-loop” design which encircles the cucumber fruit and traverses the length, cutting when it reaches the narrow stem. Thanks to this design, Vineland’s cucumber harvesting robot eliminates any risk of mistakenly cutting a main stem of the plant resulting in crop loss. In addition, fruit identification and localization software enables the arm to reach for and harvest fruit while the cart remains in motion. This reduces the time to harvest. Further research and development are underway with a goal of offering an overall ROI/payback period competitive compared to human labour.

Complementing the cucumber harvesting system is a direct-to-stem end effector for harvesting bell peppers with accompanying software ripeness determination and harvest planning. Companies interested in working with Vineland to finalize the harvesting robot design and bring it to market may contact Vineland’s business development team for more info.

For more information, please contact:

Amanda Moen, Sr. Business Advisor, Commercialization & IP

bdoadmin@vinelandresearch.com